Material Genealogy

Customers from many industries want to know that manufacturers can record and trace material usages throughout the manufacturing process. This is particularly important when there is a Quality issue involving containments and recalls. Knowing when different batches of materials are fed into the production line can also be very helpful when identifying root causes to process variations.

Tracking materials via manual recordings will not allow effective use of the data when it is needed, often urgently. The material tracking functionality in AlphaDES is integrated tightly to the data entry interfaces so that production operators have a guided and enforced approach to record the data. The built-in reports will then allow bi-directional extraction of material genealogy data just by knowing a single affected serial/lot number or material batch number.

- AlphaDES can track both raw materials and internally produced child parts that are assembled into a top-level finished product.

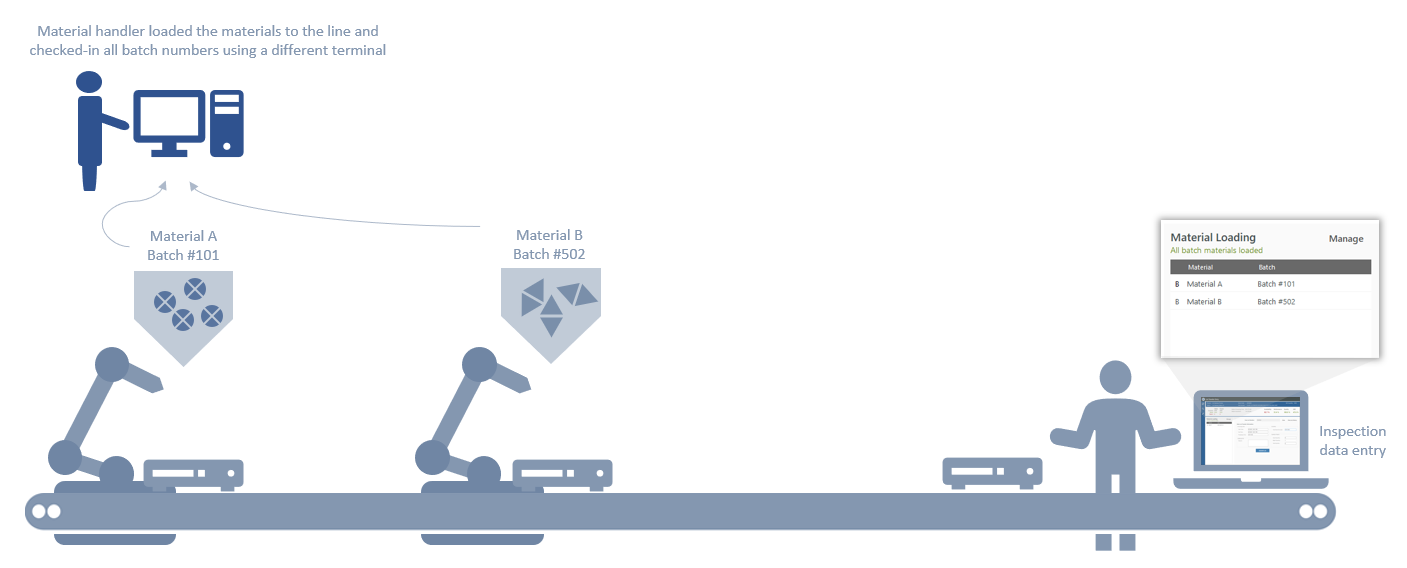

- Material batches of a station can be checked-in/out via a separate Material Management module. This can be useful when materials are loaded at a location that is far from the end-of-line data entry station.

- Both batch and serialized materials can be tracked. For serialized material, operator will be prompted to scan the material’s serial number (such as a barcode on a PCBA) for every unit of product.

- Built-in reports allow bi-directional search between products and materials.

- AlphaDES does not require the full Bill of Material from ERP system, so production can choose to track only the critical materials.

- Blocks data entry by operator if materials are not fully checked-in, thus preventing traceability gaps.

- AlphaDES not only links serial/lot numbers to material batches, check-in and check-out timestamp of materials at every station are recorded as well.

To understand more about how AlphaDES can help your factory track materials better, please feel free to get in touch with us.